Development direction of diamond wire silicon wafer cutting equipment

High wire speed and high capacity support single GW investment reduction

According to fracture mechanics theory and the properties of silicon materials, when the maximum cutting depth of diamond abrasive is greater than the critical cutting depth of silicon materials, a transition from plastic cutting to brittle fracture cutting will occur. Therefore, within the allowable range of diamond wire load, appropriately increasing the wire speed during multi-wire cutting is conducive to removing silicon materials in the ductile domain, and the surface quality of silicon wafers will be improved.

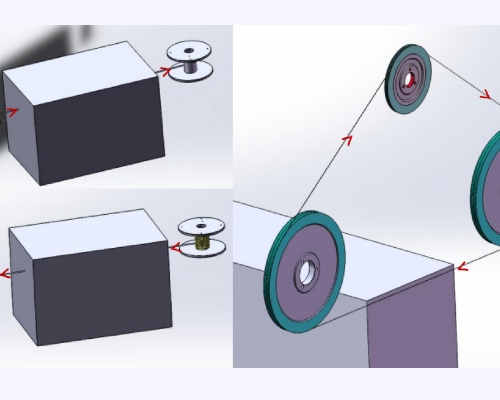

For silicon wafer cutting equipment manufacturers, while considering cost reduction, it is necessary to further improve the overall stability of the equipment, especially the stability of tension control, the stability of the spindle bearing box and the strength of the equipment. Now, the mainstream slicing line speed on the market is 1800~2100 m/min. Since 2017, the increase in the line speed of the slicer has begun to diverge. By 2019, some diamond wire slicer manufacturers are constrained by the choice of technical routes and their own R&D capabilities. The limit remains at 1800m/min, and a few manufacturers with strong R&D capabilities continue to increase the line speed to 2400m/min, Improve technical barriers. With the improvement of cutting equipment and diamond wire technology, the line speed will also be further improved.

The increase in cutting line speed, combined with the enhancement of diamond wire cutting capacity, shortens the cutting time of each knife and increases the daily production capacity of each equipment. In 2016, nearly 40 slicers were required for each GW of production capacity, but currently, with the improvement of line speed and loading capacity, there are only 16 slicers per GW of production capacity; for the improvement of single chip power, in the near future, the investment in slicers per GW will be reduced. Therefore, fixed asset investment, as well as later utility costs, maintenance costs, and labor costs will be reduced for enterprises that plan to add new capacity and plan to increase production capacity.