Diamond Wire Ring Saw Cutting NdFeB Magnets

Neodymium magnets, also known as NdFeB magnets, are tetragonal crystals formed from neodymium, iron, and boron (Neodymium 2 Iron 14B). This magnet is the second most magnetic permanent magnet available today after absolute zero holmium magnets. It is also the most commonly used rare earth magnet.

NdFeB is divided into two types: sintered NdFeB and bonded NdFeB. Bonded NdFeB is magnetic in all directions and is corrosion-resistant;

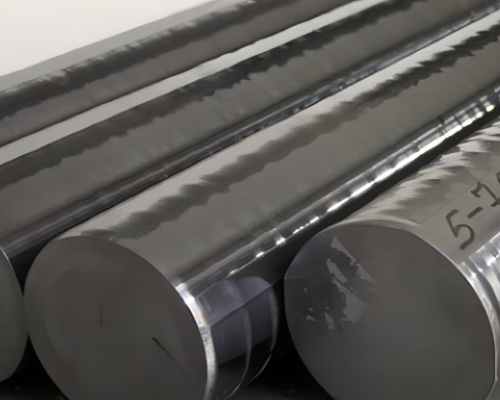

Sintered NdFeB is easy to corrode, and the surface needs electroplating. Generally, there are galvanized, nickel, environmentally friendly zinc, environmentally friendly nickel, nickel-copper-nickel, and environmentally friendly nickel-copper-nickel. Sintered NdFeB is generally divided into Axial magnetization and radial magnetization, determined according to the required working surface.

For cutting large NdFeB magnets, many manufacturers use reciprocating long wire cutting, while small NdFeB magnets are cut with an inner diameter cutting machine. The cutting efficiency of the inner diameter cutting machine is low, but sometimes cutting a small amount of NdFeB magnets does not require opening Large machine. With the rise of diamond wire trepanation saws, some manufacturers began to use diamond wire trepanation saws to cut NdFeB. The cutting efficiency is 3 times that of the inner diameter cutting machine, and it has been welcomed by many domestic manufacturers.

Sintered NdFeB permanent magnet materials have excellent magnetic properties and are widely used in electronic products, motors, medical equipment, toys, packaging, hardware machinery, aerospace and other fields.

The more common ones are permanent magnet motors, speakers, magnetic separators, computer disk drives, magnetic resonance imaging equipment and instruments.